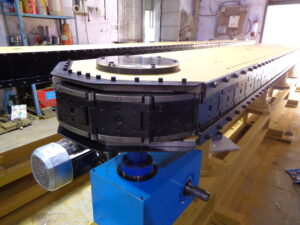

They are used for assembly automation, packaging etc. This type of conveyors are very robust & accurate. The links are precisely, machines and hardened. The length of conveyor can be customized as per requirement. The length varies from 1 meter to 6 meters. Positional accuracy is maintained through an indexing unit coupled with gear box and motor.

Youtube – https://youtu.be/VEH04bWkgIM

Dual Head Impact Press Machines are intricately designed with the aid of technologically advanced machinery and ensure high performance and low maintenance. These machines are used for two different operations in one stroke. The pressure adjustments are independent of heads and are extensively used in stationary, auto component manufacturing, electrical and electronic industry (PCB Stud fitting). This impact press can be operated in the following combinations:

Head 1 – Head 2

Riveting – Riveting

Marking – Marking

Riveting – Marking

Assembly – riveting and so on.

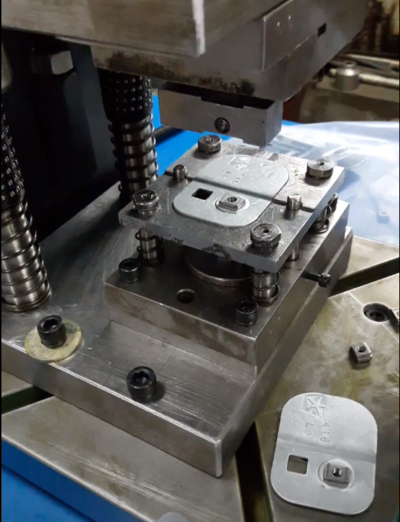

Dual Head Punching Machines are used in the metal sheet forming process by cuting, perforating and shape metals with the help of punch and press technique. This process produces an initial deformation of the material to be formed, which is followed by a shear stress which allows the material to be fractured and cut. Finally, the resulting cut piece is expelled from the punch. It is quite fast and is a very precise and effective way of forming the metal with fine finish. This machine is widely used in stamping and forming of hardware parts such as electronics, computers, PCB\’s, household appliances, automobiles etc.

This is a special application press were in hydropneumatic is placed over the rack and pinion press.

The operator can work in both options of the machine i.e, rack and pinion press and hydro pneumatic press. Honed bores and ground rams provide a long service life and a precise guidance. This machine is best suited for jobs such as Insertion of bushes, axles and bearings into housings or deep bores, Assembly of components with large installation heights etc.

The hydropneumatic press are combined with INdexing workstation for different applications at a time. Here two different presses are combined into one station to perform pressing operations, Here the advantage is two different components re ejected at a time.

Basic principle is of LOADING = PRESSING + UNLOADING

The C-Frame design offers full accessibility when manually inserting and removing parts.

Easy adaptation to different tool and part heights because of simplistic height adjustment with angular gear. Anti-rotational rectangular ram with fully adjustable, Teflon lined gibs for precise travel. No die set required. High precision due to long precise guides of the rectangular ram.

The welded press frame offers the highest stability. Space-saving and compact due to separate working cylinder for press. Suitable for Assembling, riveting, staking, swaging, crimping, marking, numbering, deforming, stamping, dismantling & for applying High force over a short distance.

Impact press works on the principle of converting kinetic energy into potential energy. This is achieved by tensioning a spring under a weighed punch which is preloaded by 6 balls, as this assembly is lifted up by hand lever, the balls release the punch which in turn strikes the job to get desired result. The mechanical advantage ratio is very high and hence however ligthly the lever is pulled, the pressure released on to the job is always consistent and thus gives a uniform finish to the job. This are used in various application such as marking , riveting , blanking, piercing, press fitting, eyeleting, assembly riveting, inserting etc.

Models available : 1.1 Ton & 3.5 Ton

Pneumatic Impact Machines are easy to use, faster than Hand Operated Press and uses dry & moisture free air to create pressure for forcing the Press Downwards and releases the air through valve. This type of machine is helpful when you want to apply heavy force or when volume of work is beyond the capabiities of Hand Operated Impact Press Machines

Model Available : 1.1 Ton & 3.5 Ton

This type of Impact Press is connected with a PLC unit that controls the functioning of the Impact Press and gives you the ability to set the amount of pressure to be released on the job as per your requirement and automate your system. This maximizes the throughput of your production unit with consistent and precise finish

In this the impact press is combined with 12 station indexing table for higher production The production rate is 35pcs per minute, here the loading is manual & ejection is automatic with a pull cylinder. The system is controlled by PLC for ease of maintenance Here the fixture can easily changed by the operator. We can design the station as per the customer requirement with pick & place system & feeding systems for higher production.

This type of Impact Press comes with a fixture that consist of 2 – hand safety switch, where the operator press the 2 hand switch & the fixture goes below the the press, which in turn gives pulse to the vertical cylinder to actuate. The operation is done and the job comes out automatically, this have counter to count the no of operations.

Textile manufacture and repair shops need a grommet press that they can rely on to do consistent work for years to come. Whether you’re installing eyelets on designer curtains, or fixing a grommet on a canvas tarp, Janesville Tool & Manufacture makes Arbor presses for grommets that will perform flawlessly.

Insert O Press are designed for deep throat depth i.e 300to 500mm. It works on the principle of converting kinetic energy into potential energy transferred to the rivet and efficiently inserts riveting on control panel bodies, marking on panels etc. These are engineered to perfection and includes higher through depth & height adjustment facilities.

2 Models are available:

1. Insert O Press – 4 Ton Press With Throat Depth 550mm

This press is used for Stainless steel studs & Standoffs in SS panels. The throat depth is of 550mm & stroke of 150mm.

2. Insert O Press – 4 Ton Press With Throat Depth 800mm

This press can be used for control panel riveting of studs, standoffs, cling nuts & inserts.

Rack and Pinion Press Machines are manually operated bench-top presses where the press force is generated with manual force applied to the lever, which starts up the transmission mechanism. Here Press Force is constant in direct relation to the manual force applied during the entire stroke. The position of the press head is adjustable. Rack & Pinion Press Machines are useful for mounting, pressing, bending etc.

This Rack & Pinion Press comes with a Return Lock Mechanism that locks the lever from returning back in case if the lever was not fully rotated by the operator. So here the operator has to complete the rotation operation or else the handle will not return back to its original position and operator will have to release the lock by hitting on the Lock Release Knob given on the left side.

The head is capable of holding the tool at 90 degrees vertical for tasks such as polishing metal objects, sanding different shapes and grinding metal pieces. (*Tool Not Included*).

It is designed for handling medium size workpieces. An enormous number of axle speeds and feeds might be accessible for penetrating various kinds of work.

Heavy box column gives the machine strength and unbending nature.

The head can be raised or brought down by a hoisting screw. Flex shaft tool stand allows telescopic adjustment. This press machine can be used to drill up to of 50 mm in distance across.

Multi Head Riveting Machine is helpful for increasing the production rate at per time with highly accurate dimension and seamless cutting. It is semi-automatic in function and equipped with powerful electrical motor. As well as, rivet machine is designed with more than one panel in parallel row for fast working speed. This is style with CNC technology which provides precised cutting and holing of the metal sheet, fasteners and bolts. Multi Head Riveting Machine is mainly used in manufacturing units to make different kinds of mechanical tools and devices. The rivet machine has computerized panel, hydraulic system and sharp blunt needles.

This type of Riveting Machine can easily set two rivets of same or different diameter concurrently either in Horizontal or Vertical direction. Thus this machine gives almost two times out put as compared to standard machine. To meet client’s specific requirements, we offer this machine in various technical specifications. The offered machine is used to rivet door hinges and other both side riveting parts etc.

Marking Cum Riveting Machine is made from high grade stainless steel and coated with heat resistant paint. These are compact in shape and have floor mounted style that occupies less space. In addition to this, rivet machine is used for making dimensionally accurate products with précised sizes and shapes.

These are easy to set-up and operate due to semi-automatic function. Marking Cum Riveting Machine is electrical in working and consumes 240 to 480 Voltage power supply.

It is excellent in providing high speed operation with great consistency & productive flow. The machine is utilized for making the holes in between the fasteners & bolts.

Orbital Riveting Machine is precision engineered to ensure that they will perform with unfailing speed, accuracy & consistent repeatability.

Quiet electric motors drive the silent orbital movement of the tool holder. The same machine, using suitable tools can flare, flange, join & swage.

Pressure for head forming is generated by either pneumatic or hydraulic power & is fully adjustable. Step less adjustment of riveting force, time, stroke & speed allows the machine to perform on a wide variety of applications such as automobile parts, switch gear, baggage industry, electronics, bicycle parts, chain assembly, locks & type writers etc.

Here the Riveting machine is combined with Rotary Indexing table for higher productivity. Indexing Table Spin Riveting Machine is the one that can be used for a variety of jobs from freely swivelling joints to clamped, torque resisting joints.

The index tables are available in various combinations of “Dwell Angle” and “Index Angle” to cater to different applications. There are various models (sizes) of index tables with different load carrying capacities.

This type of machines are fast, smooth, jerk-free, maintenance-free, clockwise/anticlockwise rotation, high indexing accuracy.

Indexing Table increases the productivity as you just have to load the job on the table and riveting or stamping is automatically done.

We have combined this same Pneumatic Toggle Press with Indexing Workstation to give more milage and production output to our customers.

Our basic principle is LOADING = UNLOADING + PRESSING OPERATION, i.e the operator loads the component and the indexing table indexes to the pressing station and at the same time the operator is loads the next component. This reduces the ideal time of operator and increases the production output by 50%.

In this double pressing station , two different components can be done, i.e two operators can sit on one workstation doing different operation ( riveitng, marking, etc).

Here the speed of indexing can be increased as per the speed of laoding the component, thus changing the traditional production methods and also reducing the manpower by 30%.

Pneumatic Toggle Press with PLC Control Panel is the one mainly used for operations on sheet metal such as riveting, piercing, clinching, stamping, etc.

This is used in mass production and more efficient way to form metal into finish product.

Pneumatic Toggle Press with PLC Control Panel is thoroughly tested on several parameters to make sure that we serve a flawless range to our customers.

Micro Toggle Press comes with smaller capacities with a robust press base.

This type machines are ideal for joining and shaping applications where components require low pressure and precise stroke depth.

Examples are applications in medical engineering, electronics manufacturing and precision mechanics.